Page not found. Your pixels are in another canvas.

Sitemap

A list of all the posts and pages found on the site. For you robots out there is an XML version available for digesting as well.

Pages

About me

Posts

portfolio

publications

Jian Luo, Wei Chen, Gen Fu

Journal of Materials Processing Technology, December 2014

Abstract

Electrical current aided friction stir welding (EFSW) is based on increasing heat generation during welding by adding a resistant heat source. The influence of current intensity to surface shaped features on welding seam was discussed. The comparison between AZ31B joints and Al 7075 joints was conducted. For the AZ31B joints, the resistant heat source promoted significant grain refinement and hardness improvement in the weld nugget zone (WNZ). It also increased plastic deformation during welding. For the Al 7075 joints, the grain size in the WNZ and heat affected zone (HAZ) increased slightly with the increase in electric current intensity. EFSW was proven to be suitable for joining high-strength alloys, such as 2Cr13Mn9Ni4 and Q235B. High microhardness values were obtained at both sides of the mechanical interlock zone.

Jian Luo, Hong Wang, Wei Chen, Longfei Li

The International Journal of Advanced Manufacturing Technology, April 2015

Abstract

Friction wear is a key factor influencing the life of friction stir welding (FSW) tools. One of the challenging problems in the field of FSW is improving anti-wear properties and extending the service life of tools. Based on Archard theory, a rigid-plastic mathematical-physical model describing the friction wear behavior of the tool during FSW process was established. The friction wear behavior and surface features of the tool during plunging and welding stage were studied by numerical and physical experiments. The effects of welding parameters and geometrical features of the tool on friction wear behavior were analyzed. 7075 aluminum alloy was chosen as the welding material and the tool was designed and manufactured by 3D printing. These numerical and physical experiments were compared. The results show that the tool fabricated from turning consisted of tempered martensite, while the tool produced from selective laser melting showed layers of banded structure with inhomogeneous directions. The average microhardness of the latter was higher than that of the former. The wear loss of the FSW tool during plunge stage increases with the increasing of the rotation speed and plunge speed. Meanwhile, the wear depth of the tool increases with raising the rotation speed at a constant welding speed. The weight of FSW tool decreases with increasing welding distance. The microstructure of the stir made by the selective laser melting is beneficial to improve the anti-wear property. The manufacturing process method can affect the tool’s lifetime seriously with the same material used. The simulation results are shown to be in good agreement with experimental data. The study also provides theoretical and practical guidance for predicting the wear of FSW tools.

Jian Luo, Shixian Li, Wei Chen, Junfeng Xiang, Hong Wang

The International Journal of Advanced Manufacturing Technology, May 2015

Abstract

The three-dimensional model for friction stir welding was established by coupling thermal, force, and flowing fields. The weld shape, surface stripes, weld defect, temperature field, and material flow behavior were predicted. The transient heat transfer phenomenon and material mixing pattern at the stir zone was primarily studied. The material flow mechanism was investigated. The experimental results strongly supported the reliability and accuracy of the model and simulation. The rotational speed to welding speed ratio Rω/Uw plays an important role in transient heat transfer, temperature field, velocity field, material mixing pattern, and weld defect appearance.

Wei Chen, Jonah Chazan, Mark Fuge

Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, December 2016

Abstract

This paper shows how to measure the complexity and reduce the dimensionality of a geometric design space. It assumes that high-dimensional design parameters actually lie in a much lower-dimensional space that represents semantic attributes. Past work has shown how to embed designs using techniques like autoencoders; in contrast, this paper quantifies when and how various embeddings are better than others. It captures the intrinsic dimensionality of a design space, the performance of recreating new designs for an embedding, and the preservation of topology of the original design space. We demonstrate this with both synthetic superformula shapes of varying non-linearity and real glassware designs. We evaluate multiple embeddings by measuring shape reconstruction error, topology preservation, and required semantic space dimensionality. Our work generates fundamental knowledge about the inherent complexity of a design space and how designs differ from one another. This deepens our understanding of design complexity in general.

Wei Chen, Mark Fuge, Jonah Chazan

Journal of Mechanical Design, March 2017

Abstract

This paper shows how to measure the intrinsic complexity and dimensionality of a design space. It assumes that high-dimensional design parameters actually lie in a much lower-dimensional space that represents semantic attributes—a design manifold. Past work has shown how to embed designs using techniques like autoencoders; in contrast, the method proposed in this paper first captures the inherent properties of a design space and then chooses appropriate embeddings based on the captured properties. We demonstrate this with both synthetic shapes of controllable complexity (using a generalization of the ellipse called the superformula) and real-world designs (glassware and airfoils). We evaluate multiple embeddings by measuring shape reconstruction error, pairwise distance preservation, and captured semantic attributes. By generating fundamental knowledge about the inherent complexity of a design space and how designs differ from one another, our approach allows us to improve design optimization, consumer preference learning, geometric modeling, and other design applications that rely on navigating complex design spaces. Ultimately, this deepens our understanding of design complexity in general.

Wei Chen, Mark Fuge

Journal of Mechanical Design, October 2017

Abstract

To solve a design problem, sometimes it is necessary to identify the feasible design space. For design spaces with implicit constraints, sampling methods are usually used. These methods typically bound the design space; that is, limit the range of design variables. But bounds that are too small will fail to cover all possible designs, while bounds that are too large will waste sampling budget. This paper tries to solve the problem of efficiently discovering (possibly disconnected) feasible domains in an unbounded design space. We propose a data-driven adaptive sampling technique—ε-margin sampling, which learns the domain boundary of feasible designs and also expands our knowledge on the design space as available budget increases. This technique is data-efficient, in that it makes principled probabilistic trade-offs between refining existing domain boundaries versus expanding the design space. We demonstrate that this method can better identify feasible domains on standard test functions compared to both random and active sampling (via uncertainty sampling). However, a fundamental problem when applying adaptive sampling to real world designs is that designs often have high dimensionality and thus require (in the worst case) exponentially more samples per dimension. We show how coupling design manifolds with ε-margin sampling allows us to actively expand high-dimensional design spaces without incurring this exponential penalty. We demonstrate this on real-world examples of glassware and bottle design, where our method discovers designs that have different appearance and functionality from its initial design set.

Wei Chen, Mark Fuge

Structural and Multidisciplinary Optimization, January 2018

Abstract

Many engineering problems require identifying feasible domains under implicit constraints. One example is finding acceptable car body styling designs based on constraints like aesthetics and functionality. Current active-learning based methods learn feasible domains for bounded input spaces. However, we usually lack prior knowledge about how to set those input variable bounds. Bounds that are too small will fail to cover all feasible domains; while bounds that are too large will waste query budget. To avoid this problem, we introduce Active Expansion Sampling (AES), a method that identifies (possibly disconnected) feasible domains over an unbounded input space. AES progressively expands our knowledge of the input space, and uses successive exploitation and exploration stages to switch between learning the decision boundary and searching for new feasible domains. We show that AES has a misclassification loss guarantee within the explored region, independent of the number of iterations or labeled samples. Thus it can be used for real-time prediction of samples’ feasibility within the explored region. We evaluate AES on three test examples and compare AES with two adaptive sampling methods — the Neighborhood-Voronoi algorithm and the straddle heuristic — that operate over fixed input variable bounds.

Wei Chen, Ashwin Jeyaseelan, Mark Fuge

Proceedings of the ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, November 2018

Abstract

Real-world designs usually consist of parts with hierarchical dependencies, i.e., the geometry of one component (a child shape) is dependent on another (a parent shape). We propose a method for synthesizing this type of design. It decomposes the problem of synthesizing the whole design into synthesizing each component separately but keeping the inter-component dependencies satisfied. This method constructs a two-level generative adversarial network to train two generative models for parent and child shapes, respectively. We then use the trained generative models to synthesize or explore parent and child shapes separately via a parent latent representation and infinite child latent representations, each conditioned on a parent shape. We evaluate and discuss the disentanglement and consistency of latent representations obtained by this method. We show that shapes change consistently along any direction in the latent space. This property is desirable for design exploration over the latent space.

Wei Chen, Kevin Chiu, Mark Fuge

AIAA Scitech 2019 Forum, January 2019

Abstract

Global optimization of aerodynamic shapes requires a large number of expensive CFD simulations because of the high dimensionality of the design space. One means to combat that problem is to reduce the dimension of the design space—for example, by constructing low dimensional parametric functions (such as PARSEC and others)—and then optimizing over those parameters instead. Such approaches require first a parametric function that compactly describes useful variation in airfoil shape—a non-trivial and error-prone task. In contrast, we propose to use a deep generative model of aerodynamic designs (specifically airfoils) that reduces the dimensionality of the optimization problem by learning from shape variations in the UIUC airfoil database. We show that our data-driven model both (1) learns realistic and compact airfoil shape representations and (2) empirically accelerates optimization convergence by over an order of magnitude.

Wei Chen, Mark Fuge

Journal of Mechanical Design, September 2019

Abstract

Real-world designs usually consist of parts with interpart dependencies, i.e., the geometry of one part is dependent on one or multiple other parts. We can represent such dependency in a part dependency graph. This paper presents a method for synthesizing these types of hierarchical designs using generative models learned from examples. It decomposes the problem of synthesizing the whole design into synthesizing each part separately but keeping the interpart dependencies satisfied. Specifically, this method constructs multiple generative models, the interaction of which is based on the part dependency graph. We then use the trained generative models to synthesize or explore each part design separately via a low-dimensional latent representation, conditioned on the corresponding parent part(s). We verify our model on multiple design examples with different interpart dependencies. We evaluate our model by analyzing the constraint satisfaction performance, the synthesis quality, the latent space quality, and the effects of part dependency depth and branching factor. This paper’s techniques for capturing dependencies among parts lay the foundation for learned generative models to extend to more realistic engineering systems where such relationships are widespread.

Wei Chen, Mark Fuge

arXiv preprint arXiv:2001.04815, January 2020

Abstract

Bayesian optimization is normally performed within fixed variable bounds. In cases like hyperparameter tuning for machine learning algorithms, setting the variable bounds is not trivial. It is hard to guarantee that any fixed bounds will include the true global optimum. We propose a Bayesian optimization approach that only needs to specify an initial search space that does not necessarily include the global optimum, and expands the search space when necessary. However, over-exploration may occur during the search space expansion. Our method can adaptively balance exploration and exploitation in an expanding space. Results on a range of synthetic test functions and an MLP hyperparameter optimization task show that the proposed method out-performs or at least as good as the current state-of-the-art methods.

Wei Chen, Faez Ahmed

ICML 2020 workshop on Negative Dependence and Submodularityfor ML, July 2020

Abstract

Deep generative models have proven useful for automatic design synthesis and design space exploration. However, they face three challenges when applied to engineering design: 1) generated designs lack diversity, 2) it is difficult to explicitly improve all the performance measures of generated designs, and 3) existing models generally do not generate high-performance novel designs, outside the domain of the training data. To address these challenges, we propose MO-PaDGAN, which contains a new Determinantal Point Processes based loss function for probabilistic modeling of diversity and performances. Through a real-world airfoil design example, we demonstrate that MO-PaDGAN expands the existing boundary of the design space towards high-performance regions and generates new designs with high diversity and performances exceeding training data.

Wei Chen, Kevin Chiu, Mark Fuge

AIAA Journal, October 2020

Abstract

Global optimization of aerodynamic shapes usually requires a large number of expensive computational fluid dynamics simulations because of the high dimensionality of the design space. One approach to combat this problem is to reduce the design space dimension by obtaining a new representation. This requires a parametric function that compactly and sufficiently describes useful variation in shapes. This paper proposes a deep generative model, Bézier-GAN, to parameterize aerodynamic designs by learning from shape variations in an existing database. The resulted new parameterization can accelerate design optimization convergence by improving the representation compactness while maintaining sufficient representation capacity. The airfoil design is used as an example to demonstrate the idea and analyze Bézier-GAN’s representation capacity and compactness. Results show that Bézier-GAN both 1) learns smooth and realistic shape representations for a wide range of airfoils and 2) empirically accelerates optimization convergence by at least two times compared with state-of-the-art parameterization methods.

Wei Chen, Faez Ahmed

Proceedings of the ASME 2020 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, November 2020

Abstract

Deep generative models are proven to be a useful tool for automatic design synthesis and design space exploration. When applied in engineering design, existing generative models face three challenges: 1) generated designs lack diversity and do not cover all areas of the design space, 2) it is difficult to explicitly improve the overall performance or quality of generated designs, and 3) existing models generate do not generate novel designs, outside the domain of the training data. In this paper, we simultaneously address these challenges by proposing a new Determinantal Point Processes based loss function for probabilistic modeling of diversity and quality. With this new loss function, we develop a variant of the Generative Adversarial Network, named “Performance Augmented Diverse Generative Adversarial Network” or PaDGAN, which can generate novel high-quality designs with good coverage of the design space. Using three synthetic examples and one real-world airfoil design example, we demonstrate that PaDGAN can generate diverse and high-quality designs. In comparison to a vanilla Generative Adversarial Network, on average, it generates samples with 28% higher mean quality score with larger diversity and without the mode collapse issue. Unlike typical generative models that usually generate new designs by interpolating within the boundary of training data, we show that PaDGAN expands the design space boundary outside the training data towards high-quality regions. The proposed method is broadly applicable to many tasks including design space exploration, design optimization, and creative solution recommendation.

Wei Chen, Faez Ahmed

Journal of Mechanical Design, November 2020

Abstract

Deep generative models are proven to be a useful tool for automatic design synthesis and design space exploration. When applied in engineering design, existing generative models face three challenges: (1) generated designs lack diversity and do not cover all areas of the design space, (2) it is difficult to explicitly improve the overall performance or quality of generated designs, and (3) existing models generally do not generate novel designs, outside the domain of the training data. In this article, we simultaneously address these challenges by proposing a new determinantal point process-based loss function for probabilistic modeling of diversity and quality. With this new loss function, we develop a variant of the generative adversarial network, named performance augmented diverse generative adversarial network (PaDGAN), which can generate novel high-quality designs with good coverage of the design space. By using three synthetic examples and one real-world airfoil design example, we demonstrate that PaDGAN can generate diverse and high-quality designs. In comparison to a vanilla generative adversarial network, on average, it generates samples with a 28% higher mean quality score with larger diversity and without the mode collapse issue. Unlike typical generative models that usually generate new designs by interpolating within the boundary of training data, we show that PaDGAN expands the design space boundary outside the training data towards high-quality regions. The proposed method is broadly applicable to many tasks including design space exploration, design optimization, and creative solution recommendation.

Wei Chen, Arun Ramamurthy

AIAA Scitech 2021 Forum, January 2021

Abstract

In aerodynamic shape optimization, the convergence and computational cost are greatly affected by the representation capacity and compactness of the design space. Previous research has demonstrated that using a deep generative model to parameterize two-dimensional (2D) airfoils achieves high representation capacity/compactness, which significantly benefits shape optimization. In this paper, we propose a deep generative model, Free-Form Deformation Generative Adversarial Networks (FFD-GAN), that provides an efficient parameterization for three-dimensional (3D) aerodynamic/hydrodynamic shapes like aircraft wings, turbine blades, car bodies, and hulls. The learned model maps a compact set of design variables to 3D surface points representing the shape. We ensure the surface smoothness and continuity of generated geometries by incorporating an FFD layer into the generative model. We demonstrate FFD-GAN's performance using a wing shape design example. The results show that FFD-GAN can generate realistic designs and form a reasonable parameterization. We further demonstrate FFD-GAN's high representation compactness and capacity by testing its design space coverage, the feasibility ratio of the design space, and its performance in design optimization. We demonstrate that over 94% feasibility ratio is achieved among wings randomly generated by the FFD-GAN, while FFD and B-spline only achieve less than 31%. We also show that the FFD-GAN leads to an order of magnitude faster convergence in a wing shape optimization problem, compared to the FFD and the B-spline parameterizations.

Amin Heyrani Nobari, Wei Chen, Faez Ahmed

Proceedings of the ASME 2021 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, March 2021

Abstract

Typical engineering design tasks require the effort to modify designs iteratively until they meet certain constraints, i.e., performance or attribute requirements. Past work has proposed ways to solve the inverse design problem, where desired designs are directly generated from specified requirements, thus avoid the trial and error process. Among those approaches, the conditional deep generative model shows great potential since 1) it works for complex high-dimensional designs and 2) it can generate multiple alternative designs given any condition. In this work, we propose a conditional deep generative model, Range-GAN, to achieve automatic design synthesis subject to range constraints. The proposed model addresses the sparse conditioning issue in data-driven inverse design problems by introducing a label-aware self-augmentation approach. We also propose a new uniformity loss to ensure generated designs evenly cover the given requirement range. Through a real-world example of constrained 3D shape generation, we show that the label-aware self-augmentation leads to an average improvement of 14% on the constraint satisfaction for generated 3D shapes, and the uniformity loss leads to a 125% average increase on the uniformity of generated shapes' attributes. This work laid the foundation for data-driven inverse design problems where we consider range constraints and there are sparse regions in the condition space.

Amin Heyrani Nobari, Wei Chen, Faez Ahmed

Proceedings of the 27th ACM SIGKDD Conference on Knowledge Discovery and Data Mining (KDD ’21), June 2021

Abstract

Engineering design tasks often require synthesizing new designs that meet desired performance requirements. The conventional design process, which requires iterative optimization and performance evaluation, is slow and dependent on initial designs. Past work has used conditional generative adversarial networks (cGANs) to enable direct design synthesis for given target performances. However, most existing cGANs are restricted to categorical conditions. Recent work on Continuous conditional GAN (CcGAN) tries to address this problem, but still faces two challenges: 1) it performs poorly on non-uniform performance distributions, and 2) the generated designs may not cover the entire design space. We propose a new model, named Performance Conditioned Diverse Generative Adversarial Network (PcDGAN), which introduces a singular vicinal loss combined with a Determinantal Point Processes (DPP) based loss function to enhance diversity. PcDGAN uses a new self-reinforcing score called the Lambert Log Exponential Transition Score (LLETS) for improved conditioning. Experiments on synthetic problems and a real-world airfoil design problem demonstrate that PcDGAN outperforms state-of-the-art GAN models and improves the conditioning likelihood by 69% in an airfoil generation task and up to 78% in synthetic conditional generation tasks and achieves greater design space coverage. The proposed method enables efficient design synthesis and design space exploration with applications ranging from CAD model generation to metamaterial selection.

Wei Chen, Faez Ahmed

Applied Soft Computing, September 2021

Abstract

Multi-objective optimization is key to solving many Engineering Design problems, where design parameters are optimized for several performance indicators. However, optimization results are highly dependent on how the designs are parameterized. Researchers have shown that deep generative models can learn compact design representations, providing a new way of parameterizing designs to achieve faster convergence and improved optimization performance. Despite their success in capturing complex distributions, existing generative models face three challenges when used for design problems: 1) generated designs have limited design space coverage, 2) the generator ignores design performance, and 3) the new parameterization is unable to represent designs beyond training data. To address these challenges, we propose MO-PaDGAN, which adds a Determinantal Point Processes based loss function to the generative adversarial network to simultaneously model diversity and (multi-variate) performance. MO-PaDGAN can thus improve the performances and coverage of generated designs, and even generate designs with performances exceeding those from training data. When using MO-PaDGAN as a new parameterization in multi-objective optimization, we can discover much better Pareto fronts even though the training data do not cover those Pareto fronts. In a real-world multi-objective airfoil design example, we demonstrate that MO-PaDGAN achieves, on average, a 186% improvement in the hypervolume indicator when compared to the vanilla GAN or other state-of-the-art parameterization methods.

Amin Heyrani Nobari, Wei Chen, Faez Ahmed

Journal of Mechanical Design, September 2021

Abstract

Typical engineering design tasks require the effort to modify designs iteratively until they meet certain constraints, i.e., performance or attribute requirements. Past work has proposed ways to solve the inverse design problem, where desired designs are directly generated from specified requirements, thus avoid the trial and error process. Among those approaches, the conditional deep generative model shows great potential since 1) it works for complex high-dimensional designs and 2) it can generate multiple alternative designs given any condition. In this work, we propose a conditional deep generative model, Range-GAN, to achieve automatic design synthesis subject to range constraints. The proposed model addresses the sparse conditioning issue in data-driven inverse design problems by introducing a label-aware self-augmentation approach. We also propose a new uniformity loss to ensure generated designs evenly cover the given requirement range. Through a real-world example of constrained 3D shape generation, we show that the label-aware self-augmentation leads to an average improvement of 14% on the constraint satisfaction for generated 3D shapes, and the uniformity loss leads to a 125% average increase on the uniformity of generated shapes' attributes. This work laid the foundation for data-driven inverse design problems where we consider range constraints and there are sparse regions in the condition space.

Qiuyi Chen, Jun Wang, Phillip Pope, Wei Chen, Mark Fuge

Journal of Mechanical Design, October 2021

Abstract

This paper shows how to use conditional generative models in 2D airfoil optimization to probabilistically predict good initialization points within the vicinity of the optima given the input boundary conditions, thus warm starting and accelerating further optimization. We accommodate the possibility of multiple optimal designs corresponding to the same input boundary condition and take this inversion ambiguity into account when designing our prediction framework. To this end, we first employ the conditional formulation of our previous work BezierGAN---Conditional BezierGAN (CBGAN)---as a baseline, then introduce its sibling conditional entropic BezierGAN (CEBGAN), which is based on optimal transport regularized with entropy. Compared with CBGAN, CEBGAN overcomes mode collapse plaguing conventional GANs, improves the average lift-drag (C_l/C_d) efficiency of airfoil predictions from 80.8% of the optimal value to 95.8%, and meanwhile accelerates the training process by 30.7%. Furthermore, we investigate the unique ability of CEBGAN to produce a log-likelihood lower bound that may help select generated samples of higher performance (e.g., aerodynamic performance). In addition, we provide insights into the performance differences between these two models with low-dimensional toy problems and visualizations. These results and the probabilistic formulation of this inverse problem justify the extension of our GAN-based inverse design paradigm to other inverse design problems or broader inverse problems.

Wei Chen, Doksoo Lee, Wei Chen

AAAI 2022 Workshop on AI for Design and Manufacturing (ADAM), December 2021

Abstract

Deep generative models have demonstrated effectiveness in learning compact and expressive design representations that significantly improve geometric design optimization. However, these models do not consider the uncertainty introduced by manufacturing or fabrication. Past work that quantifies such uncertainty often makes simplified assumptions on geometric variations, while the "real-world" uncertainty and its impact on design performance are difficult to quantify due to the high dimensionality. To address this issue, we propose a Generative Adversarial Network-based Design under Uncertainty Framework (GAN-DUF), which contains a deep generative model that simultaneously learns a compact representation of nominal (ideal) designs and the conditional distribution of fabricated designs given any nominal design. We demonstrated the framework on two real-world engineering design examples and showed its capability of finding the solution that possesses better performances after fabrication.

Wei Chen, Arun Ramamurthy

World Intellectual Property Organization, December 2021

Abstract

A system and method for synthesis and optimization of smoothed surfaced three-dimensional (3D) objects uses a trainable generative adversarial network (GAN). A generator network of the GAN includes a deconvolutional neural network configured to receive a latent vector and to generate control points and weights. A Bézier layer in the generator uses the control points and weights to generate surface points of a simulated 3D surface according to a parametric Bézier curve. A GAN discriminator network includes a convolutional neural network configured to discriminate between generated surface points and surface points corresponding to training data stored in a database. The convolutional network also predicts latent vector statistics through convolution of parameters.

Jun Wang, Wei Chen, Daicong Da, Mark Fuge, Rahul Rai

Computer Methods in Applied Mechanics and Engineering, May 2022

Abstract

Variable-density cellular structures can overcome connectivity and manufacturability issues of topologically optimized structures, particularly those represented as discrete density maps. However, the optimization of such cellular structures is challenging due to the multiscale design problem. Past work addressing this problem generally either only optimizes the volume fraction of single-type unit cells but ignoring the effects of unit cell geometry on properties, or considers the geometry–property relation but builds this relation via heuristics. In contrast, we propose a simple yet more principled way to accurately model the property to geometry mapping using a conditional deep generative model, named Inverse Homogenization Generative Adversarial Network (IH-GAN). It learns the conditional distribution of unit cell geometries given properties and can realize the one-to-many mapping from properties to geometries. We further reduce the complexity of IH-GAN by using the implicit function parameterization to represent unit cell geometries. Results show that our method can 1) generate various unit cells that satisfy given material properties with high accuracy ($R^2$ scores between target properties and properties of generated unit cells > 98%) and 2) improve the optimized structural performance over the conventional variable-density single-type structure. In the minimum compliance example, our IH-GAN generated structure achieves a 79.7% reduction in concentrated stress and an extra 3.03% reduction in displacement. In the target deformation examples, our IH-GAN generated structure reduces the target matching error by 86.4% and 79.6% for two test cases, respectively. We also demonstrated that the connectivity issue for multi-type unit cells can be solved by transition layer blending.

Doksoo Lee, Yu-Chin Chan, Wei Chen, Liwei Wang, Anton van Beek, Wei Chen

Proceedings of the ASME 2021 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, September 2022

Abstract

Inspired by the recent achievements of machine learning in diverse domains, data-driven metamaterials design has emerged as a compelling paradigm that can unlock the potential of multiscale architectures. The model-centric research trend, however, lacks principled frameworks dedicated to data acquisition, whose quality propagates into the downstream tasks. Often built by naive space-filling design in shape descriptor space, metamaterial datasets suffer from property distributions that are either highly imbalanced or at odds with design tasks of interest. To this end, we present t-METASET: an active-learning-based data acquisition framework aiming to guide both diverse and task-aware data generation. Distinctly, we seek a solution to a commonplace yet frequently overlooked scenario at early stages of data-driven design of metamaterials: when a massive (~O(10^4 )) shape-only library has been prepared with no properties evaluated. The key idea is to harness a data-driven shape descriptor learned from generative models, fit a sparse regressor as a start-up agent, and leverage metrics related to diversity to drive data acquisition to areas that help designers fulfill design goals. We validate the proposed framework in three deployment cases, which encompass general use, task-specific use, and tailorable use. Two large-scale mechanical metamaterial datasets are used to demonstrate the efficacy. Applicable to general image-based design representations, t-METASET could boost future advancements in data-driven design.

Doksoo Lee, Yu-Chin Chan, Wei Chen, Liwei Wang, Anton van Beek, Wei Chen

Journal of Mechanical Design, September 2022

Abstract

Inspired by the recent achievements of machine learning in diverse domains, data-driven metamaterials design has emerged as a compelling paradigm that can unlock the potential of multiscale architectures. The model-centric research trend, however, lacks principled frameworks dedicated to data acquisition, whose quality propagates into the downstream tasks. Often built by naive space-filling design in shape descriptor space, metamaterial datasets suffer from property distributions that are either highly imbalanced or at odds with design tasks of interest. To this end, we present t-METASET: an active-learning-based data acquisition framework aiming to guide both diverse and task-aware data generation. Distinctly, we seek a solution to a commonplace yet frequently overlooked scenario at early stages of data-driven design of metamaterials: when a massive (~O(10^4 )) shape-only library has been prepared with no properties evaluated. The key idea is to harness a data-driven shape descriptor learned from generative models, fit a sparse regressor as a start-up agent, and leverage metrics related to diversity to drive data acquisition to areas that help designers fulfill design goals. We validate the proposed framework in three deployment cases, which encompass general use, task-specific use, and tailorable use. Two large-scale mechanical metamaterial datasets are used to demonstrate the efficacy. Applicable to general image-based design representations, t-METASET could boost future advancements in data-driven design.

Wei Chen, Doksoo Lee, Oluwaseyi Balogun, Wei Chen

Proceedings of the ASME 2021 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, September 2022

Abstract

Deep generative models have demonstrated effective- ness in learning compact and expressive design represen- tations that significantly improve geometric design op- timization. However, these models do not consider the uncertainty introduced by manufacturing or fabrication. Past work that quantifies such uncertainty often makes simplifying assumptions on geometric variations, while the “real-world”, “free-form” uncertainty and its impact on design performance are difficult to quantify due to the high dimensionality. To address this issue, we propose a Generative Adversarial Network-based Design under Un- certainty Framework (GAN-DUF), which contains a deep generative model that simultaneously learns a compact representation of nominal (ideal) designs and the condi- tional distribution of fabricated designs given any nom- inal design. This opens up new possibilities of 1) build- ing a universal uncertainty quantification model compat- ible with both shape and topological designs, 2) model- ing free-form geometric uncertainties without the need to make any assumptions on the distribution of geometric variability, and 3) allowing fast prediction of uncertain- ties for new nominal designs. We can combine the pro- posed deep generative model with robust design optimiza- tion or reliability-based design optimization for design under uncertainty. We demonstrated the framework on two real-world engineering design examples and showed its capability of finding the solution that possesses better performance after fabrication.

Wei Chen, Doksoo Lee, Oluwaseyi Balogun, Wei Chen

Journal of Mechanical Design, September 2022

Abstract

Deep generative models have demonstrated effectiveness in learning compact and expressive design representations that significantly improve geometric design optimization. However, these models do not consider the uncertainty introduced by manufacturing or fabrication. The past work that quantifies such uncertainty often makes simplifying assumptions on geometric variations, while the “real-world,” “free-form” uncertainty and its impact on design performance are difficult to quantify due to the high dimensionality. To address this issue, we propose a generative adversarial network-based design under uncertainty framework (GAN-DUF), which contains a deep generative model that simultaneously learns a compact representation of nominal (ideal) designs and the conditional distribution of fabricated designs given any nominal design. This opens up new possibilities of (1) building a universal uncertainty quantification model compatible with both shape and topological designs, (2) modeling free-form geometric uncertainties without the need to make any assumptions on the distribution of geometric variability, and (3) allowing fast prediction of uncertainties for new nominal designs. We can combine the proposed deep generative model with robust design optimization or reliability-based design optimization for design under uncertainty. We demonstrated the framework on two real-world engineering design examples and showed its capability of finding the solution that possesses better performance after fabrication.

Hengrui Zhang, Wei Chen, Akshay Iyer, Daniel W Apley, Wei Chen

Scientific Reports, October 2022

Abstract

Data-driven design shows the promise of accelerating materials discovery but is challenging due to the prohibitive cost of searching the vast design space of chemistry, structure, and synthesis methods. Bayesian Optimization (BO) employs uncertainty-aware machine learning models to select promising designs to evaluate, hence reducing the cost. However, BO with mixed numerical and categorical variables, which is of particular interest in materials design, has not been well studied. In this work, we survey frequentist and Bayesian approaches to uncertainty quantification of machine learning with mixed variables. We then conduct a systematic comparative study of their performances in BO using a popular representative model from each group, the random forest-based Lolo model (frequentist) and the latent variable Gaussian process model (Bayesian). We examine the efficacy of the two models in the optimization of mathematical functions, as well as properties of structural and functional materials, where we observe performance differences as related to problem dimensionality and complexity. By investigating the machine learning models' predictive and uncertainty estimation capabilities, we provide interpretations of the observed performance differences. Our results provide practical guidance on choosing between frequentist and Bayesian uncertainty-aware machine learning models for mixed-variable BO in materials design.

research

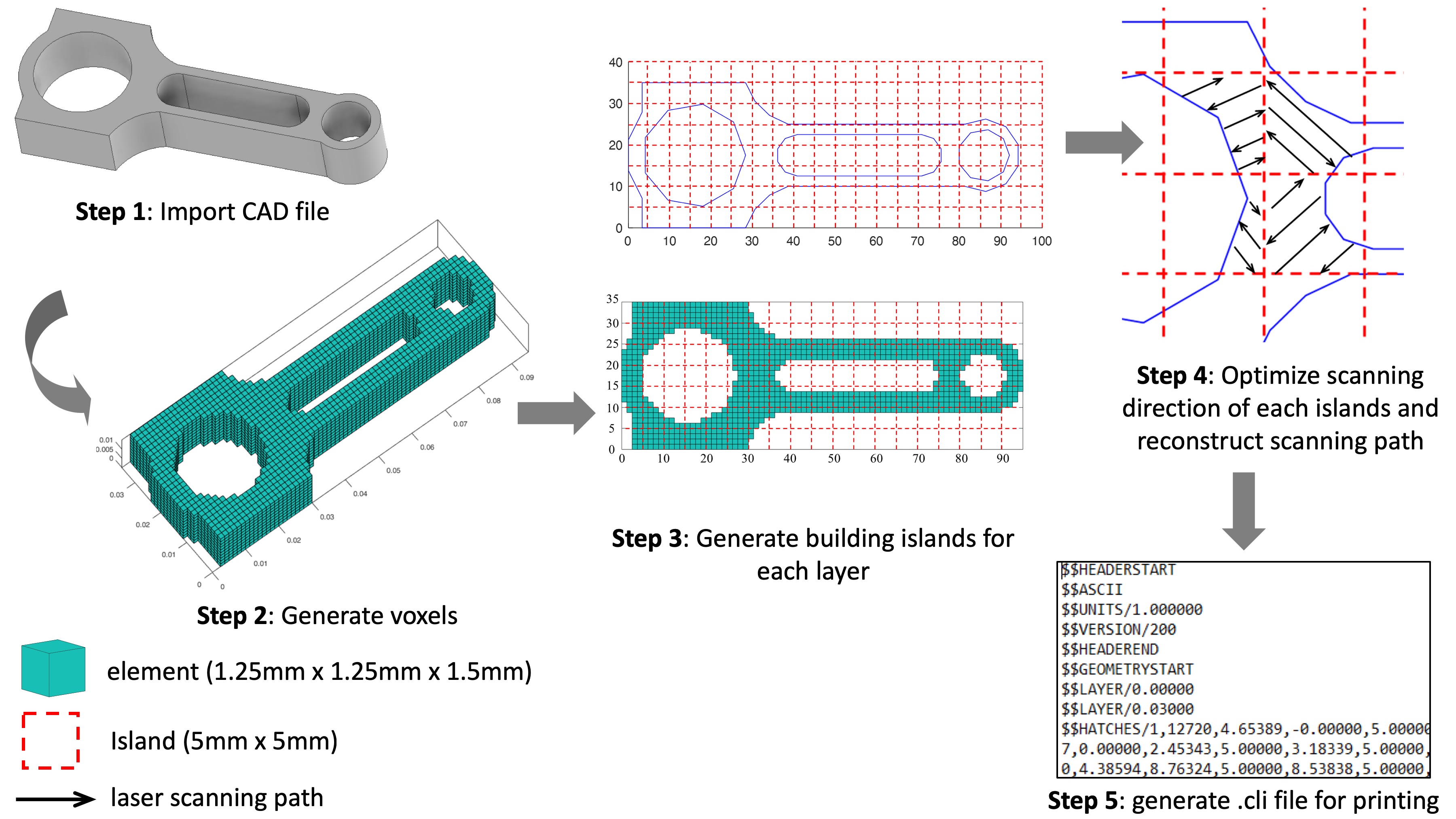

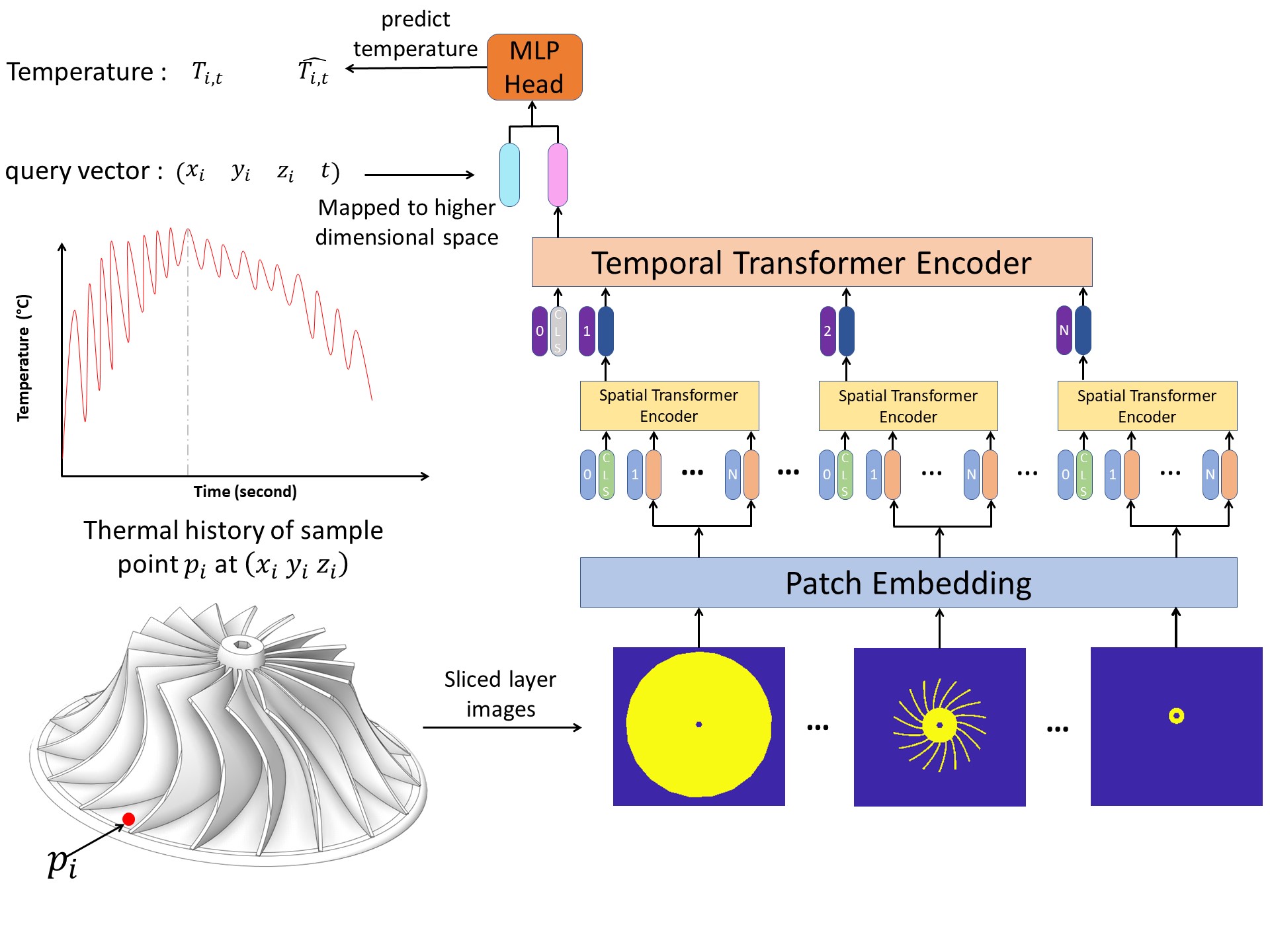

Qian Chen, Jikai Liu, Xuan Liang, Albert To

Computer Methods in Applied Mechanics and Engineering 360, 112719

Link Paper Github

Qian Chen, Hunter Taylor, Akihiro Takezawa, Xuan Liang, Xavier Jimemez, Ryan Wicker, Albert To

Additive Manufacturing 46, 102116

Link Paper Github

Qian Chen, Albert To

Github

talks

This work shows how to measure the complexity and reduce the dimensionality of a geometric design space. We assume that high-dimensional design parameters actually lie in a much lower-dimensional space that represents semantic attributes. Past work has shown how to embed designs using techniques like autoencoders; in contrast, this work quantifies when and how various embeddings are better than others. It captures the intrinsic dimensionality of a design space, the performance of recreating new designs for an embedding, and the preservation of topology of the original design space. We demonstrate this with both synthetic superformula shapes of varying non-linearity and real glassware designs. We evaluate multiple embeddings by measuring shape reconstruction error, topology preservation, and required semantic space dimensionality. Our work generates fundamental knowledge about the inherent complexity of a design space and how designs differ from one another. This deepens our understanding of design complexity in general.

Real-world designs usually consist of parts with hierarchical dependencies, i.e., the geometry of one component (a child shape) is dependent on another (a parent shape). We propose a method for synthesizing this type of design. It decomposes the problem of synthesizing the whole design into synthesizing each component separately but keeping the inter-component dependencies satisfied. This method constructs a two-level generative adversarial network to train two generative models for parent and child shapes, respectively. We then use the trained generative models to synthesize or explore parent and child shapes separately via a parent latent representation and infinite child latent representations, each conditioned on a parent shape. We evaluate and discuss the disentanglement and consistency of latent representations obtained by this method. We show that shapes change consistently along any direction in the latent space. This property is desirable for design exploration over the latent space.

Global optimization of aerodynamic shapes requires a large number of expensive CFD simulations because of the high dimensionality of the design space. One means to combat that problem is to reduce the dimension of the design space—for example, by constructing low dimensional parametric functions (such as PARSEC and others)—and then optimizing over those parameters instead. Such approaches require first a parametric function that compactly describes useful variation in airfoil shape—a non-trivial and error-prone task. In contrast, we propose to use a deep generative model of aerodynamic designs (specifically airfoils) that reduces the dimensionality of the optimization problem by learning from shape variations in the UIUC airfoil database. We show that our data-driven model both (1) learns realistic and compact airfoil shape representations and (2) empirically accelerates optimization convergence by over an order of magnitude.

Deep generative models have proven useful for automatic design synthesis and design space exploration. However, they face three challenges when applied to engineering design: 1) generated designs lack diversity, 2) it is difficult to explicitly improve all the performance measures of generated designs, and 3) existing models generally do not generate high-performance novel designs, outside the domain of the training data. To address these challenges, we propose MO-PaDGAN, which contains a new Determinantal Point Processes based loss function for probabilistic modeling of diversity and performances. Through a real-world airfoil design example, we demonstrate that MO-PaDGAN expands the existing boundary of the design space towards high-performance regions and generates new designs with high diversity and performances exceeding training data.

Deep generative models are proven to be a useful tool for automatic design synthesis and design space exploration. When applied in engineering design, existing generative models face three challenges: 1) generated designs lack diversity and do not cover all areas of the design space, 2) it is difficult to explicitly improve the overall performance or quality of generated designs, and 3) existing models generate do not generate novel designs, outside the domain of the training data. In this work, we simultaneously address these challenges by proposing a new Determinantal Point Processes based loss function for probabilistic modeling of diversity and quality. With this new loss function, we develop a variant of the Generative Adversarial Network, named “Performance Augmented Diverse Generative Adversarial Network” or PaDGAN, which can generate novel high-quality designs with good coverage of the design space. Using three synthetic examples and one real-world airfoil design example, we demonstrate that PaDGAN can generate diverse and high-quality designs. In comparison to a vanilla Generative Adversarial Network, on average, it generates samples with 28% higher mean quality score with larger diversity and without the mode collapse issue. Unlike typical generative models that usually generate new designs by interpolating within the boundary of training data, we show that PaDGAN expands the design space boundary outside the training data towards high-quality regions. The proposed method is broadly applicable to many tasks including design space exploration, design optimization, and creative solution recommendation.

In aerodynamic shape optimization, the convergence and computational cost are greatly affected by the representation capacity and compactness of the design space. Previous research has demonstrated that using a deep generative model to parameterize two-dimensional (2D) airfoils achieves high representation capacity/compactness, which significantly benefits shape optimization. In this work, we propose a deep generative model, Free-Form Deformation Generative Adversarial Networks (FFD-GAN), that provides an efficient parameterization for three-dimensional (3D) aerodynamic/hydrodynamic shapes like aircraft wings, turbine blades, car bodies, and hulls. The learned model maps a compact set of design variables to 3D surface points representing the shape. We ensure the surface smoothness and continuity of generated geometries by incorporating an FFD layer into the generative model. We demonstrate FFD-GAN’s performance using a wing shape design example. The results show that FFD-GAN can generate realistic designs and form a reasonable parameterization. We further demonstrate FFD-GAN’s high representation compactness and capacity by testing its design space coverage, the feasibility ratio of the design space, and its performance in design optimization. We demonstrate that over 94% feasibility ratio is achieved among wings randomly generated by the FFD-GAN, while FFD and B-spline only achieve less than 31%. We also show that the FFD-GAN leads to an order of magnitude faster convergence in a wing shape optimization problem, compared to the FFD and the B-spline parameterizations.

Deep generative models have demonstrated effectiveness in learning compact and expressive design representations that significantly improve geometric design optimization. However, these models do not consider the uncertainty introduced by manufacturing or fabrication. Past work that quantifies such uncertainty often makes simplified assumptions on geometric variations, while the “real-world” uncertainty and its impact on design performance are difficult to quantify due to the high dimensionality. To address this issue, we propose a Generative Adversarial Network-based Design under Uncertainty Framework (GAN-DUF), which contains a deep generative model that simultaneously learns a compact representation of nominal (ideal) designs and the conditional distribution of fabricated designs given any nominal design. We demonstrated the framework on two real-world engineering design examples and showed its capability of finding the solution that possesses better performances after fabrication.

Cellular structures with controlled local structures can realize heterogeneous material properties and hence enable a much wider range of functions than homogeneous structures. However, the design of heterogeneous cellular structures is challenging due to the high degrees of design freedom. We propose a simple yet principled way to achieve the fast design of heterogeneous cellular structures. This method uses physics-based optimization to find the optimal material property distribution under given design requirements, and uses a conditional generative model, named Inverse Homogenization Generative Adversarial Network (IH-GAN), to find the local structures that correspond to the optimal material properties. Results show that compared to the conventional variable-density approach, our method achieves a 3.03% reduction in displacement in a compliance minimization problem, and reduces the errors by around 80% in two target deformation problems.

Deep generative models have demonstrated effectiveness in learning compact and expressive design representations that significantly improve geometric design optimization. However, these models do not consider the uncertainty introduced by manufacturing or fabrication. Past work that quantifies such uncertainty often makes simplifying assumptions on geometric variations, while the “real-world”, “free-form” uncertainty and its impact on design performance are difficult to quantify due to the high dimensionality. To address this issue, we propose a Generative Adversarial Network-based Design under Uncertainty Framework (GAN-DUF), which contains a deep generative model that simultaneously learns a compact representation of nominal (ideal) designs and the conditional distribution of fabricated designs given any nominal design. This opens up new possibilities of 1) building a universal uncertainty quantification model compatible with both shape and topological designs, 2) modeling free-form geometric uncertainties without the need to make any assumptions on the distribution of geometric variability, and 3) allowing fast prediction of uncertainties for new nominal designs. We can combine the proposed deep generative model with robust design optimization or reliability-based design optimization for design under uncertainty. We demonstrated the framework on two real-world engineering design examples and showed its capability of finding the solution that possesses better performances after fabrication.